Rolled and shaped from high-strength hot-dip galvanized steel according to AS 1397 G450Z275 / G450Z350 standards, LYSAGHT ® ZINC HI-TEN Z & C section purlins are automatically cut and punched according to customer requirements.

SIZE AND GEOMETRIC CHARACTERISTICS

LYSAGHT® Z purlin

LYSAGHT® Z Purlin: The Z section has one wide wing and one narrow wing, with dimensions such that two sections of the same size can overlap tightly, making them suitable for lap splicing.

Continuous length purlins are more economical, but overlapping purlins double the metal thickness at the mid-span support. Overlapping connections increase the strength of the section at the location with the largest bending moment and shear force, thereby increasing the load-carrying capacity and stiffness of the system.

LYSAGHT® Z purlins can also be used in single spans. For shorter spans, it is possible to use continuous spans over two or more spans without overlapping – thus reducing deflection compared to a single span – but does not provide the strength advantage of an overlapping system.

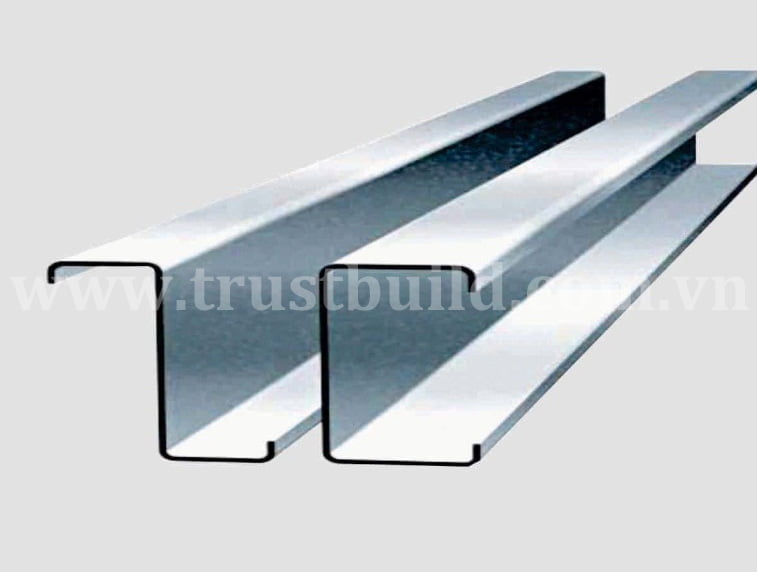

LYSAGHT® C purlin

LYSAGHT® C purlin: C section has 2 equal arms and is suitable for simple spanning spans. For shorter spans, they can be used continuously over 2 or more spans with butt joints, thereby reducing deflection compared to single spans. C purlins cannot be overlapped.

Z & C SECTION SIZE

LYSAGHT® PURLIN® C&Z

OUTSTANDING ADVANTAGES

• Ability to exceed large spans

LYSAGHT® Z&C purlins are manufactured from high-strength steel G450Mpa, allowing for very large spans while still ensuring deflection within the allowable range.

• Simple installation, low cost

LYSAGHT® Z&C purlins are cut and punched according to the project’s design and can be installed simply and accurately. Using high-strength galvanized steel, lightens the weight of the roof system while still ensuring the ability to bear large loads, reducing construction foundation costs.

• Long-lasting beauty – Save on maintenance costs

Galvanized steel protects against corrosion and rust, saves on maintenance costs, and brings beauty and peace to your project.

• Diverse thickness and sizes

LYSAGHT® Z&C purlins have many cross-sections of 100,150,200,250,300,350,400 and thicknesses from 1.2 to 3.0 to meet different aperture and design requirements.

• Check by actual experiment

The bearing capacity of purlins and connections has been confirmed through calculations and experiments at BlueScope’s NATA-certified laboratory in Australia.

• Synchronises accessories

LYSAGHT® Z&C purlins are supplied complete with bracing systems, gusset plates and galvanized bolts to ensure material compatibility and long life for the project.